One of the key stages during chocolate production is tempering, an advanced technique that requires skill and concentration, that can cause the product to fail on the production line if done badly. Careful tempering is essential to a successful production run that minimises the risk of customer dissatisfaction. But what is the chocolate tempering process and why is it so important in commercial settings? We’ll cover both of these below.

What Is Tempering Chocolate?

Chocolate tempering – or “crystallisation” – is the process of heating up and cooling down chocolate in order to stabilise it for use in confectionery and baking.

Crystallisation refers to the crystal formation in the cocoa butter changing as the temperature changes up and down. Cocoa butter crystals can exist in six forms, but only one of those forms produces the perfect chocolate. The formation of the crystals post-tempering ultimately decides the quality of the finished chocolate product.

Why Is Tempering Chocolate So Important?

Tempering helps to move cocoa butter through the first four stages of crystal formation, with the fifth stage being the first general “chocolate” stage, and the final sixth stage being the ultimate end goal of shiny, snappable chocolate.

Untempered chocolate can be recognised by:

- Its dull surface

- Its difficulty in being removed from the mould

- Its crumbly texture

- Its low melting point

- Its white marks or spots

The benefits of tempering include giving the chocolate a smooth and glossy finish, as well as making sure it will not melt easily when it’s handled. Additionally, a smooth chocolate product is likely to give that satisfactory “snap”, and to have the expected texture of chocolate (hard and crisp). This glossiness also makes properly tempered chocolate easy to remove from its mould.

Properly tempered chocolate is also far easier to mould into shapes and adhere to patterns, will have the correct melting point as opposed to softening in room temperature, and will be less likely to bloom or turn gritty or crumbly.

How Can Automation Help Chocolate Tempering?

Temperature control on a production line is crucial and every degree, one way or the other, can make a difference to the saleability of a finished chocolate product.

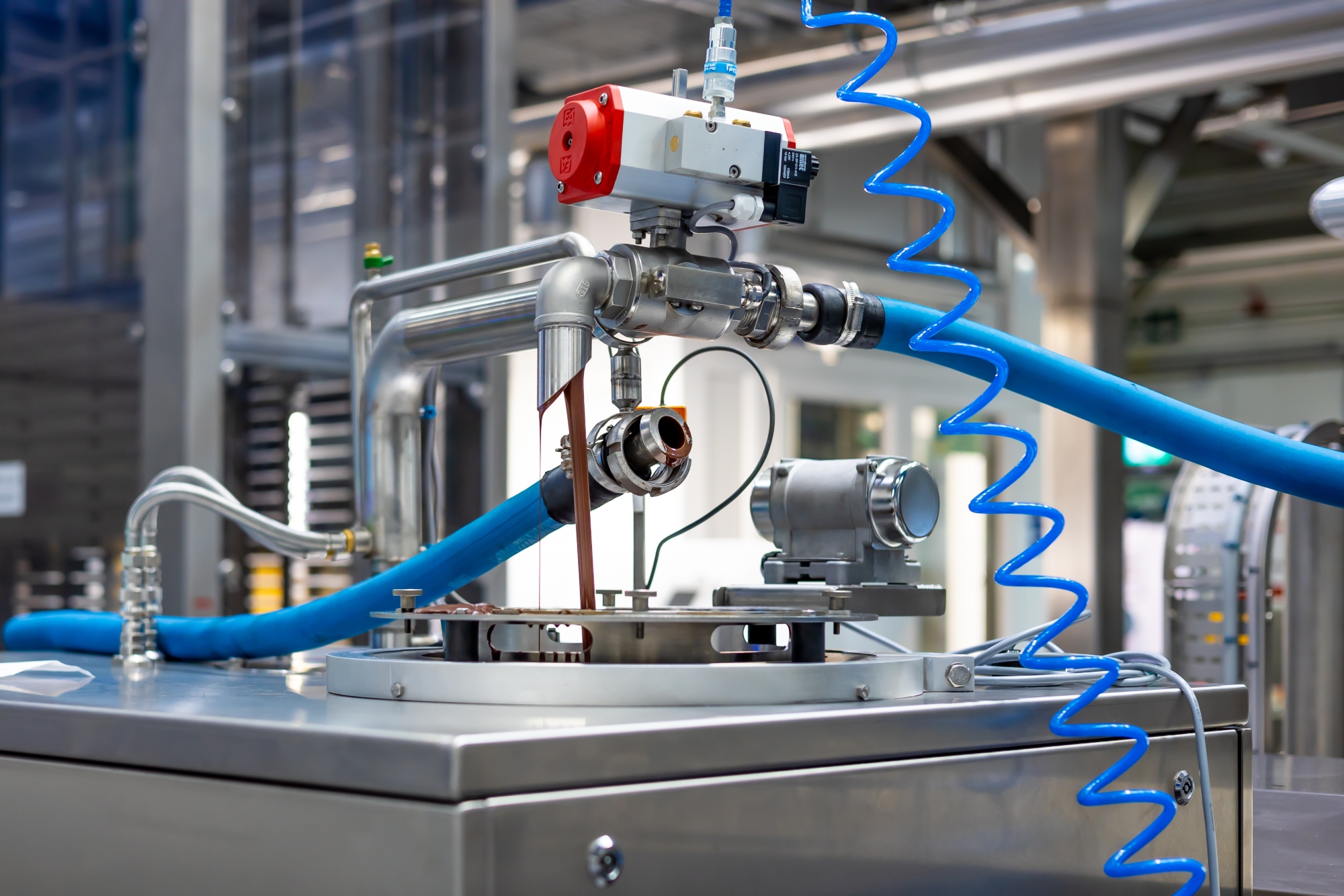

With automation you can achieve superior temperature control and monitoring to the decimal point, allowing you to entrust the most important aspect of tempering to machinery. This can save substantial time and free up other employees to focus on other tasks on the production line. Additionally, machines may be more sensitive than humans at detecting slight temperature changes and may be able to flag up problems and course-correct much more quickly and effectively.

Premier Forrester’s bespoke confectionery solutions can help your business to tackle complex confectionery processes, such as chocolate tempering. We understand how difficult it is to ensure perfection and top quality when mass producing product, so we have made sure our chocolate tempering units are suitable for businesses of all sizes looking to mass-produce. With a vast range of confectionary tools and equipment, we have a solution that is perfect for any and all of your business’s production needs.