Chocolate Demoulding Systems

The demoulding process is a critical step in chocolate production, ensuring the final products retain their shape and have a uniform, professional and high-quality finish.

Premier Forrester can supply industrial chocolate demoulding systems as individual equipment pieces or part of a complete chocolate moulding line. These robotic systems are flexible and can be used for a variety of tasks, including handling moulds or as a replacement for cooling spirals.

We have more than 25 years of experience in sourcing industrial chocolate-making machinery and will help you find the right engineering solutions for your business. Our exceptional after-sales team are also available to support your new equipment with everything from installation to operator training, servicing and more.

Image Gallery

Our Chocolate Demoulding Systems

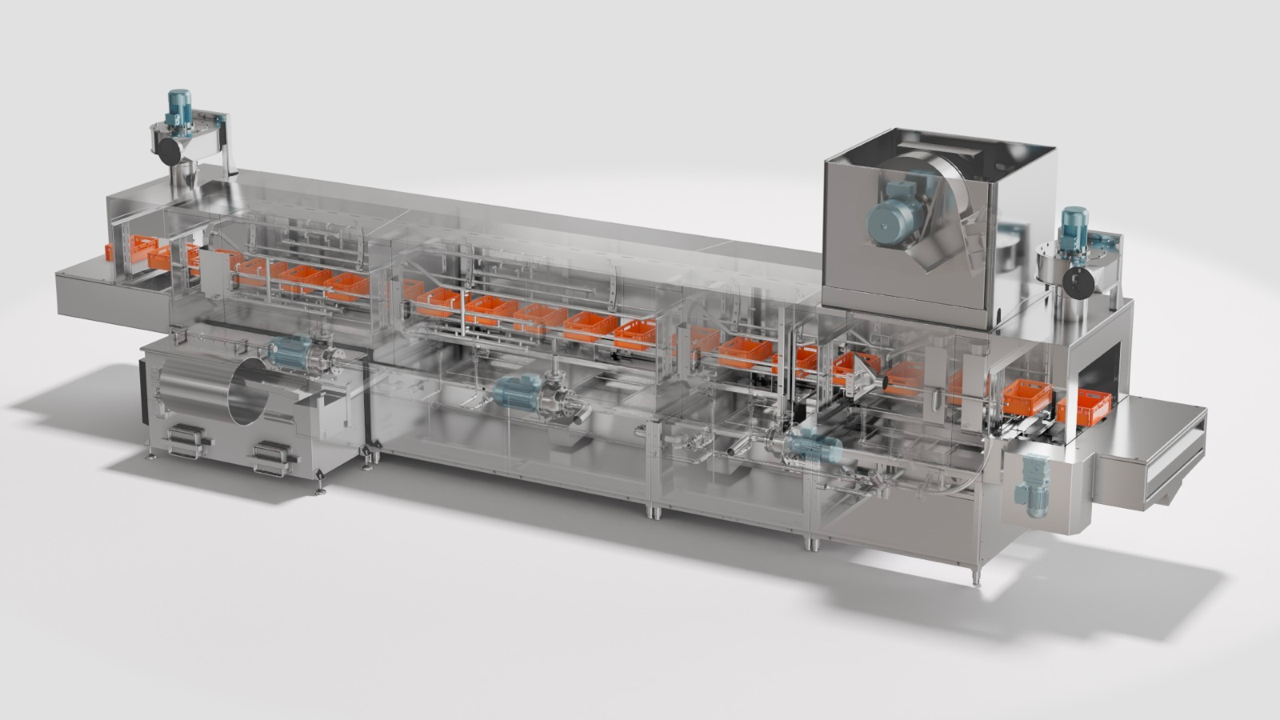

- Precision Demoulding: The system is designed to release demould chocolates delicately and accurately, without compromising their shape or appearance.

- Temperature Control: The machinery has been designed with mechanisms to control and optimise temperatures, ensuring chocolates are at the right consistency for easy demoulding.

- Automated efficiency: Incorporates automated processes to enhance efficiency and meet the demands of high-volume industrial chocolate production.

Product Specifications

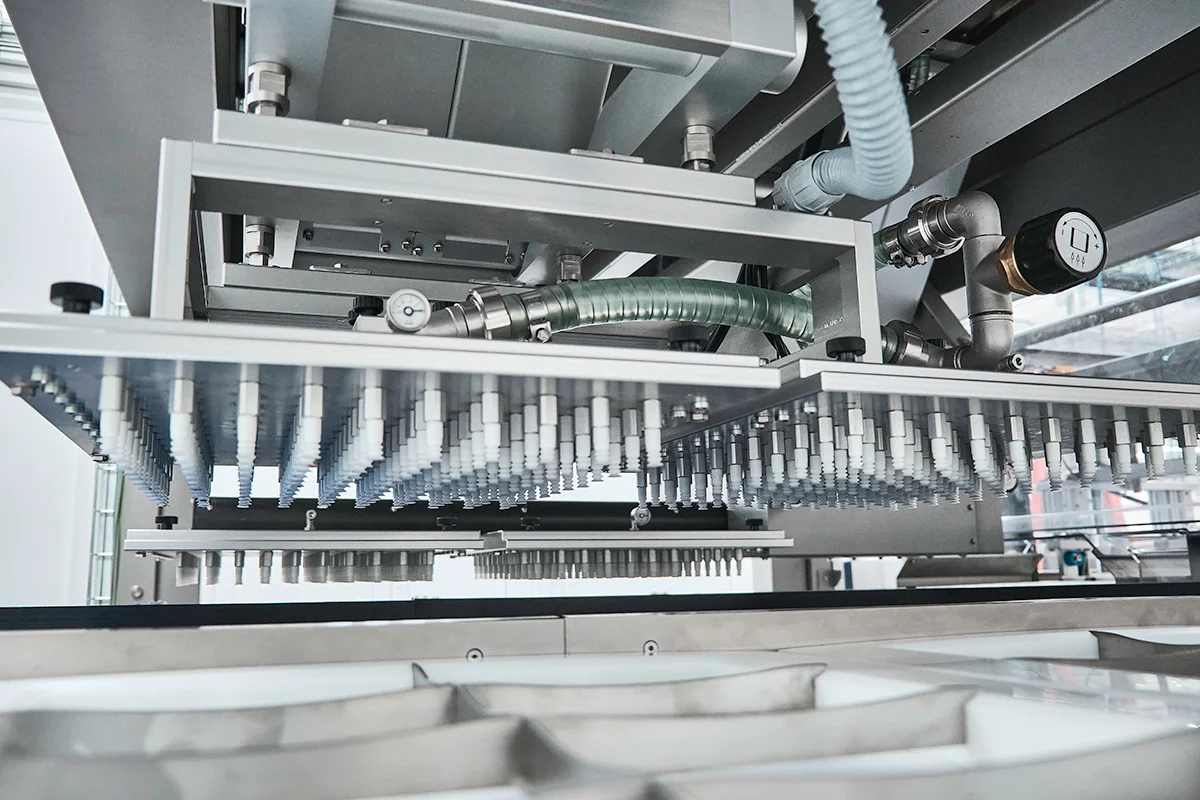

Hi-flex

- A handling system with 3-D motion

- Used for edge trimming, base stripping and demoulding

- Gearless linear servo robot system

- Precision better than 0.1mm

- The ultimate low-maintenance “pick-and-place” robot

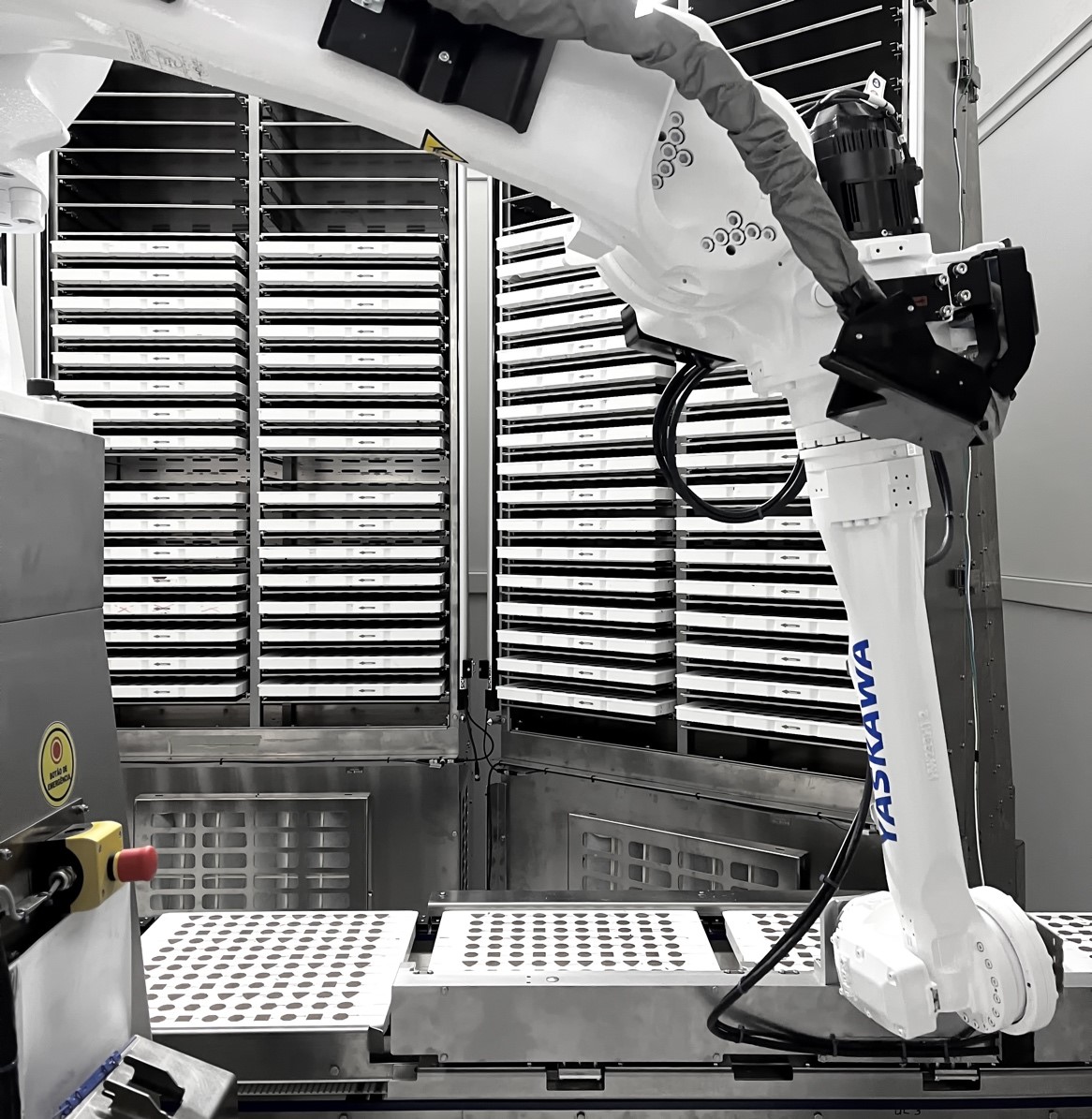

Robot

- Yaskawa Robot

- The most versitle system

- Working ranges: 300-2400mm

- Payloads: for tools from 3-100kg

- Speeds: up to 24 cycles/min

- Used for cooling and heating cells, mould handling, changing station, bottom and edge stripping, demoulding

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?