Chocolate Hygiene Systems

These hygiene systems are designed to maintain cleanliness on industrial chocolate production lines, preventing cross-contamination between batches and ensuring a high-quality finished product.

The automated machines streamline the cleaning process by programmatically controlling parameters, such as temperature and pressure, to optimise cleaning performance.

Whether you need a chocolate mould washing machine or a complete tunnel cleaning system, Premier Forrester can help source the right equipment and machinery for your business.

We have more than 25 years of experience in the chocolate and confectionery industry and provide an exceptional after-sales support service as part of our equipment sales. Get in touch today to discuss your requirement.

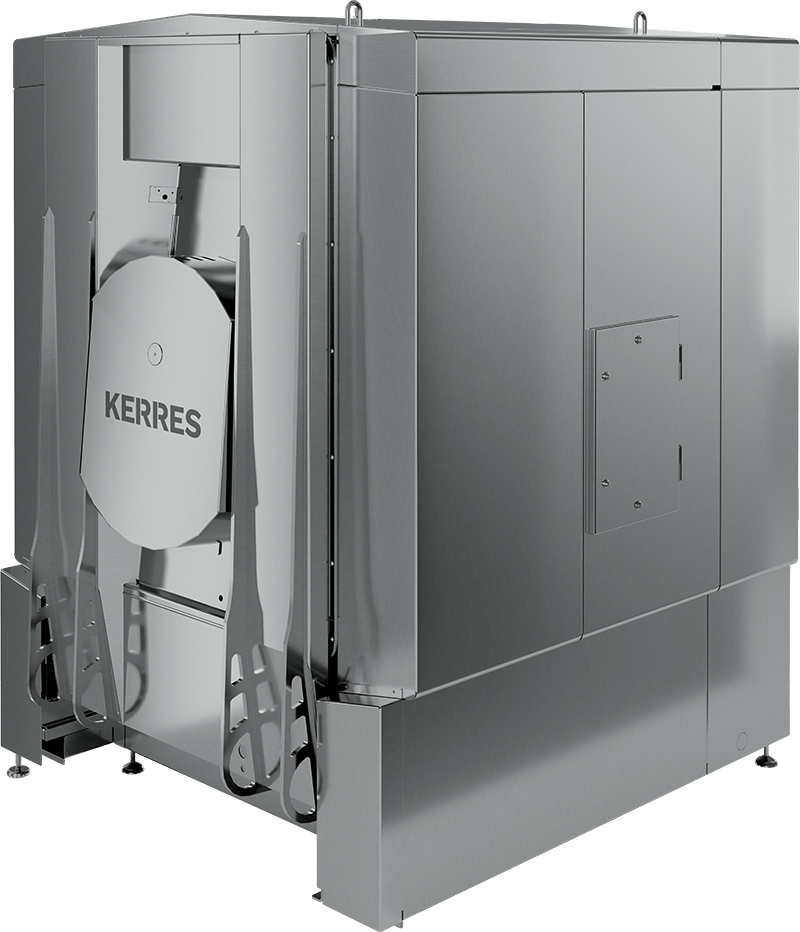

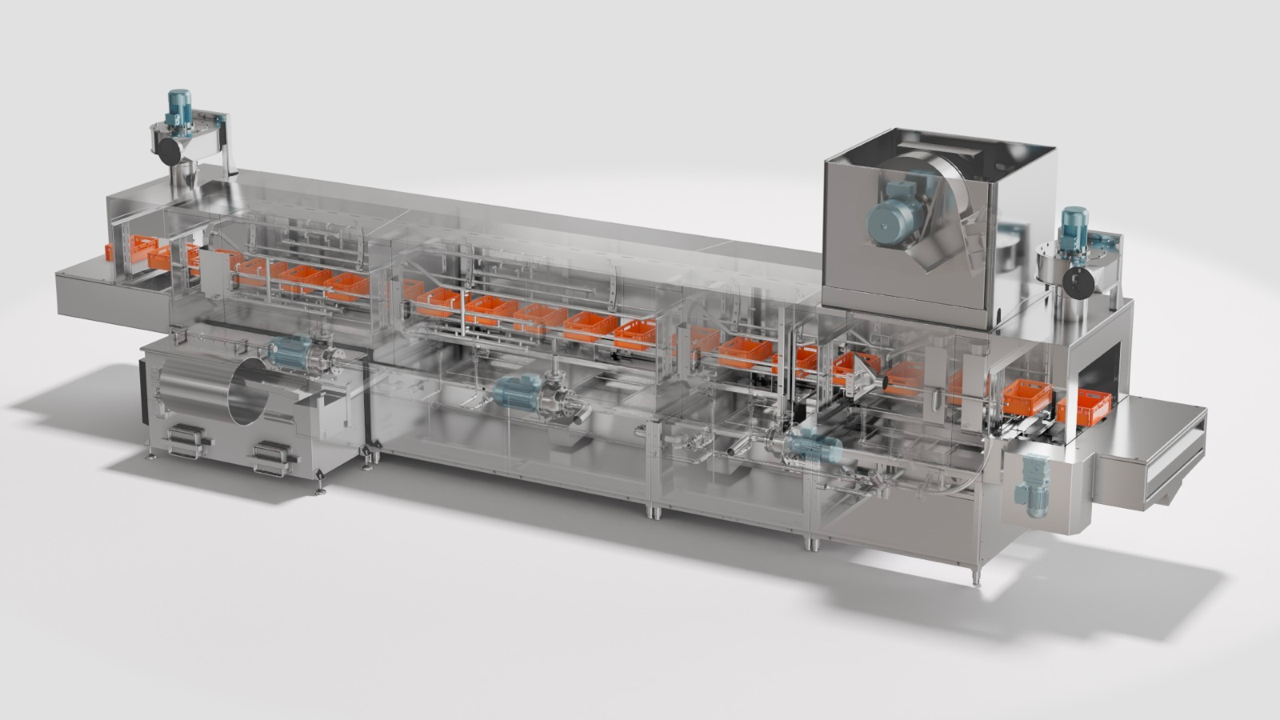

Kerres Batch Hygiene System

Our Hygiene Systems include:

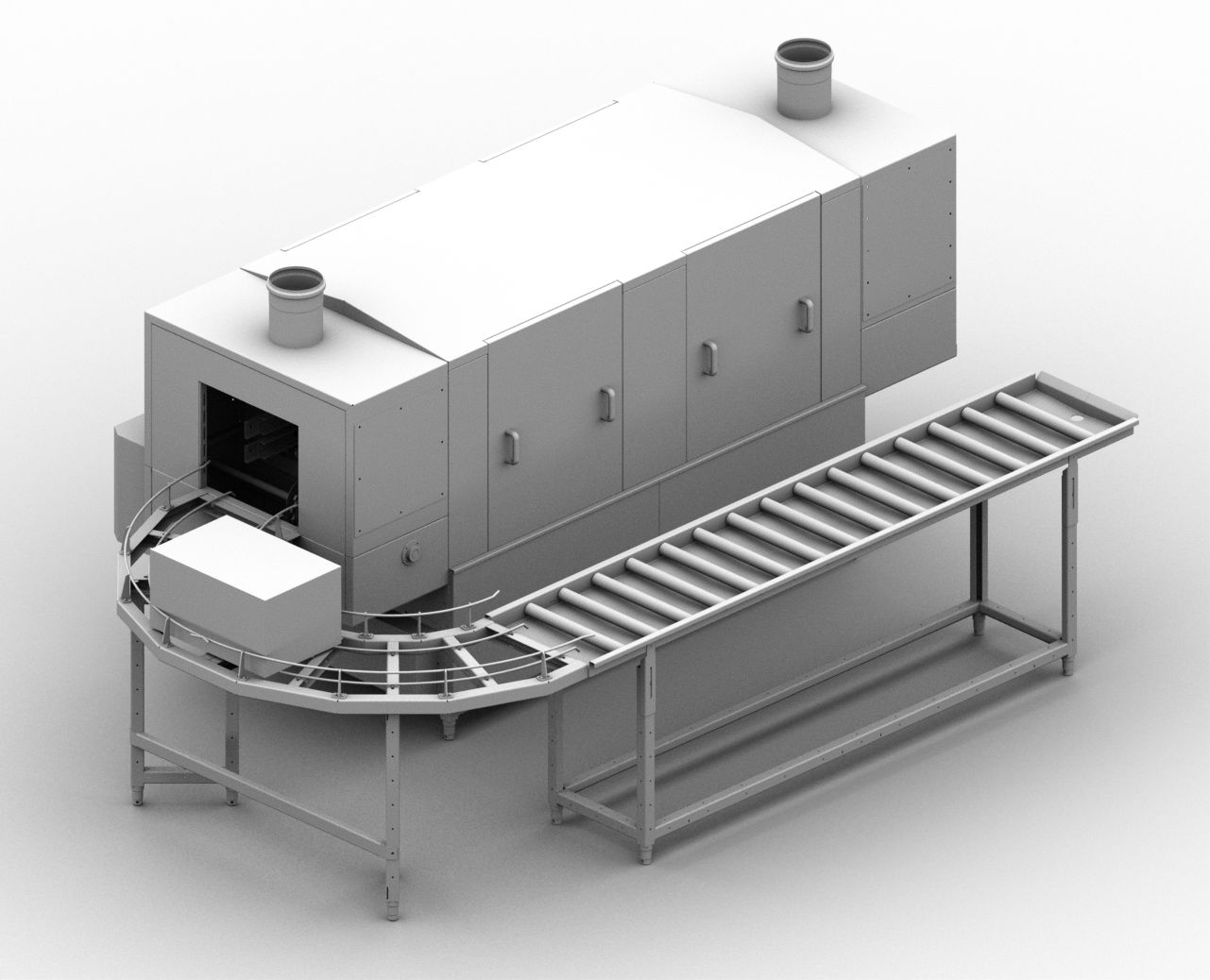

- Continuous Tunnel Cleaning: A continuous cleaning solution designed to achieve the strict food hygiene regulations for products such as chocolate moulds, crates and plaques.

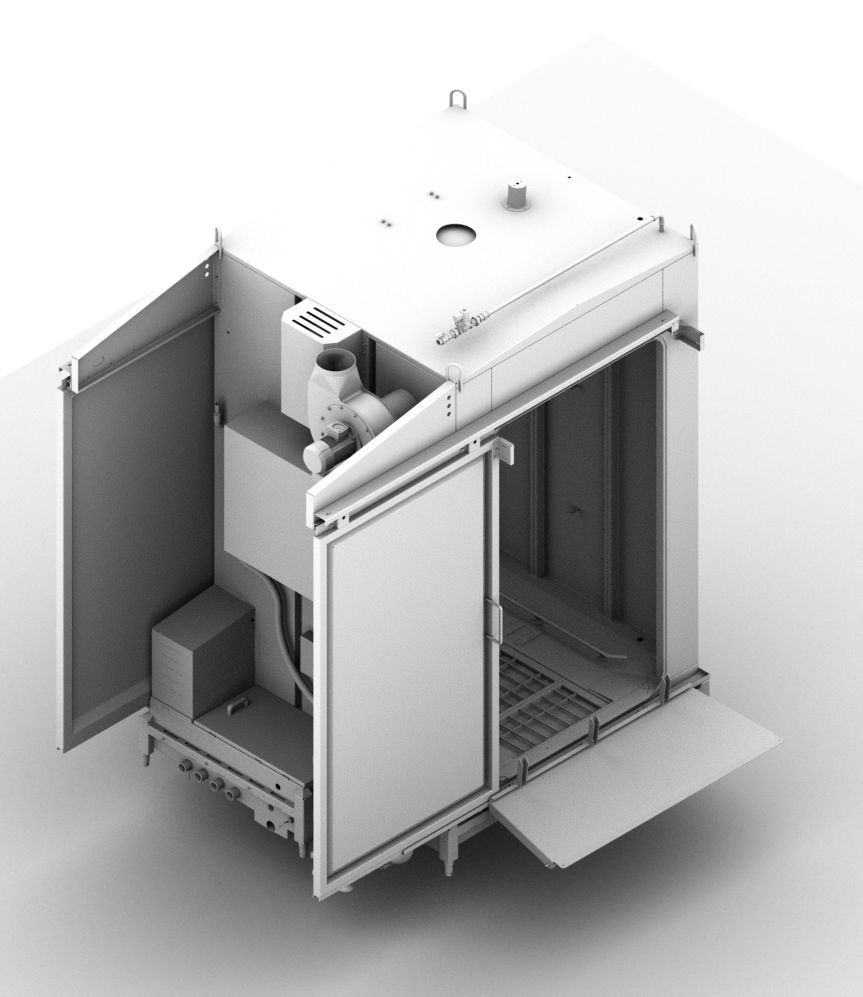

- Batch Cleaning: Front-loading cleaning systems for multiple applications including Dolav, large containers, bins, utensil trolleys and more.

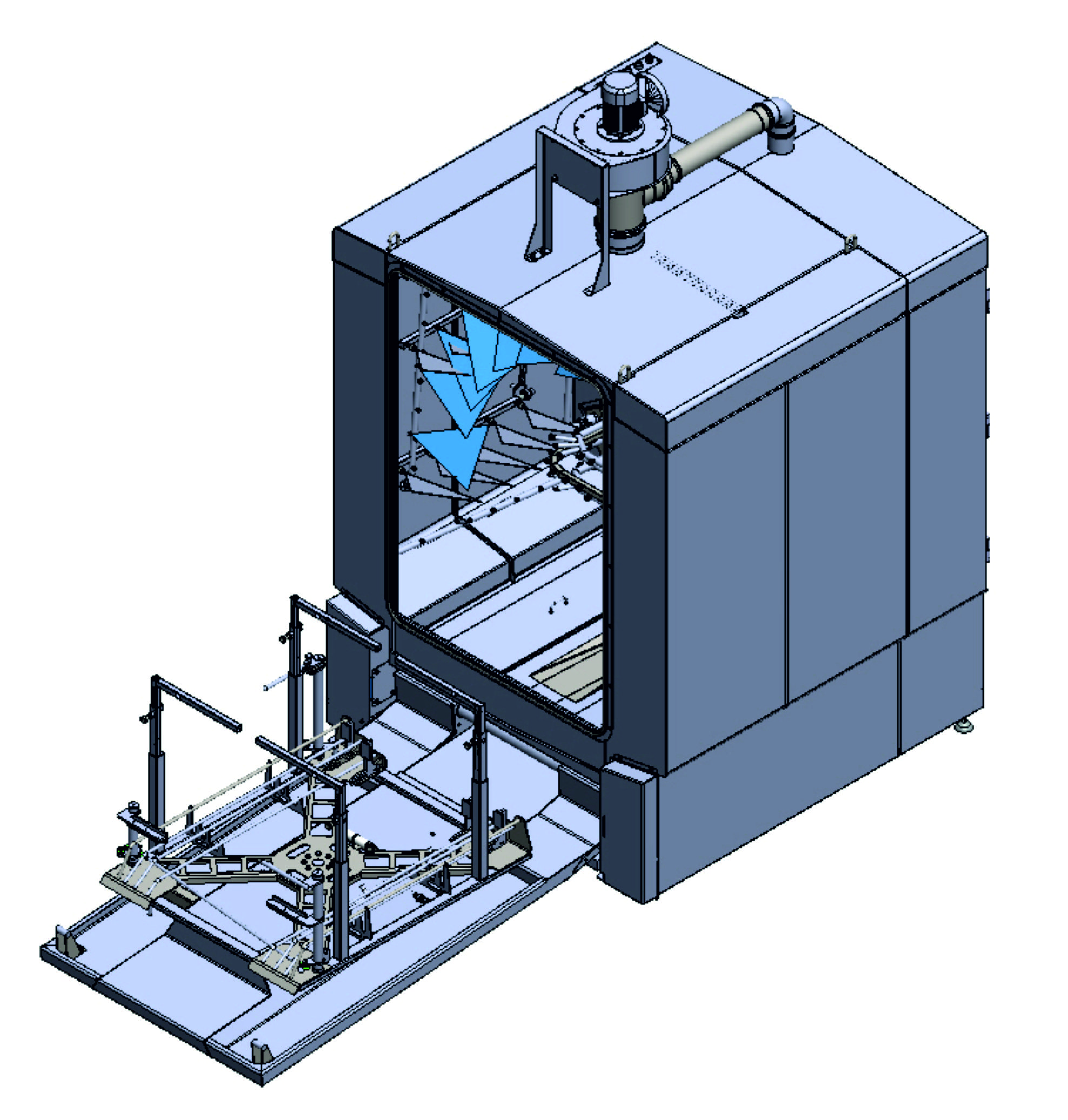

- Trolley Cleaning: Multifunctional batch systems that allow trolleys of different sizes to be cleaned in one operation.

- Chocolate Mould Washing: Chocolate mould cleaning solutions that help producers meet comprehensive hygiene and quality assurance standards.

- Smoke Stick Washing: Fast, thorough and automated cleaning systems for smoking utensils.

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?