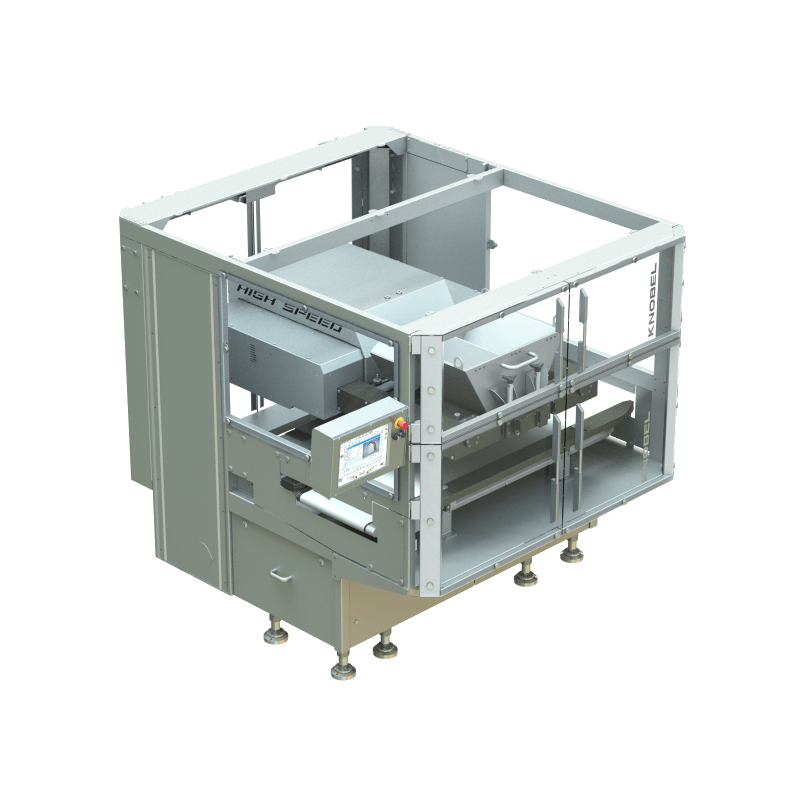

Chocolate Mould Heating & Cooling Spirals

Mould cooling and heating spirals offer temperature-controlled precision for your chocolate manufacturing processes.

Specifically designed for the unique demands of professional chocolate manufacturing, these spiral systems transport moulds and finished products along a curved ramp. The system can be seamlessly integrated with existing production lines for maximum efficiency.

Our experienced team can help you select the right heating and cooling spiral for your production needs. We also offer after-sales support and can assist with everything from installation to training and sourcing spare parts.

Image Gallery

Key Product Features

- Precise temperature control: Our spiral systems offer precise heating and cooling options to ensure optimal readiness on production lines.

- Versatile production support: Whether preparing chocolate moulds for use or enhancing the quality of finished products, these heating and cooling systems are adaptable for a variety of manufacturing needs.

- Perfect finished product: Our heating and cooling spiral systems will help you achieve the ideal consistency in your chocolate products, creating a flawless finish.

Product Specifications

- Transported without fastening – loose mould system

- Uniformed cooling and heating

- Cooling section: 9-500m

- Mould width: up to 650mm

- Options: double tower/two-part spiral

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?