Inclusion Depositors

Inclusion depositing machines effectively deposit chocolate mixtures that contain a high level of inclusions, both in terms of size and volume. This allows manufacturers to create products with a variety of textures and flavour profiles.

Premier Forrester have more than 25 years of experience in supplying engineering solutions for chocolate production lines. Whether you simply need to replace a piece of equipment or are looking to streamline your whole process, we can help source the right inclusion depositor for your needs.

We also provide an exceptional after-sales service for all customers – ensuring your equipment continues to run smoothly, and supporting your team with servicing, spare parts and more.

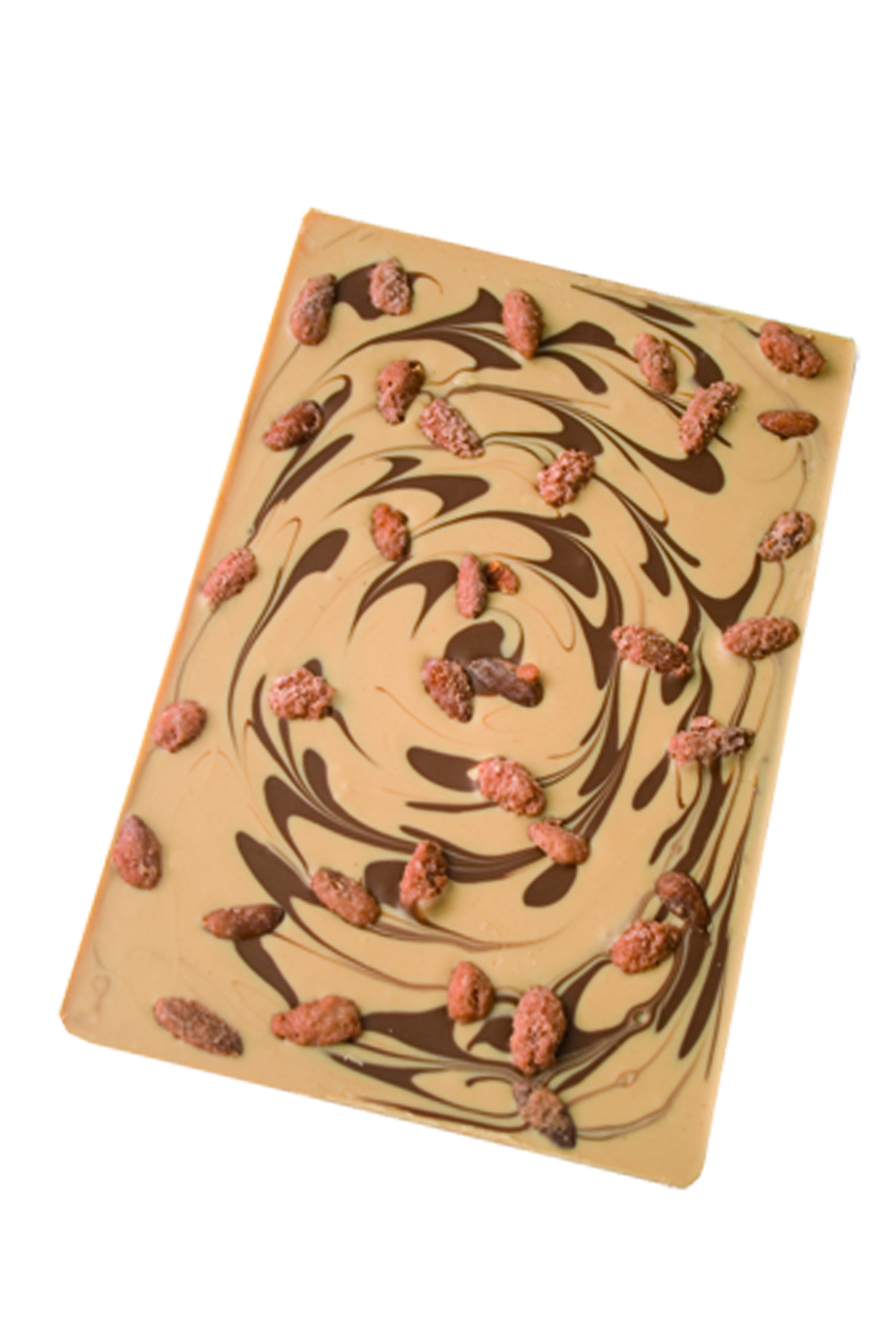

Image Gallery

Key Product Features

- Adjustable settings: Inclusion depositors offer customisable settings to handle different types and sizes of inclusions for diverse product options.

- Automated operation: Similar to solid chocolate depositors, inclusion depositing machines contribute to efficient, automated production processes.

- Consistent quality: By effectively mixing and depositing inclusion-rich masses, these machines ensure uniformity and high quality in your final chocolate products.

Product Specifications

Alpha

- Machine types: TCM 9, TCM 36/72, TCM 72/144

- Piston stoke: 52mm/60mm/70mm

- Z-axis: 150mm/300mm

- X-axis: 150mm/300mm

- Rifles: 35-90mm

- Pistons: 10-30mm

Beta

- Machine types: TCM 9, TCM 18

- Piston stoke: 52mm/60mm

- Z-axis: 150mm

- Y-axis: 150mm

- X-axis: 150mm

- Rifles: 30/2-45mm

- Pistons: 6-30mm

Eta/Theta

- Machine types: TCM 9/18, TCM 36/72, TCM 72/144

- Piston stoke: 52mm/60mm/70mm

- Z-axis: 150mm

- Y-axis: 150/300mm

- X-axis: Eta – 300mm/400mm, Theta – 300mm/500mm

- Rifles: 30/2-90mm

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?