3D Chocolate Decorating Machines

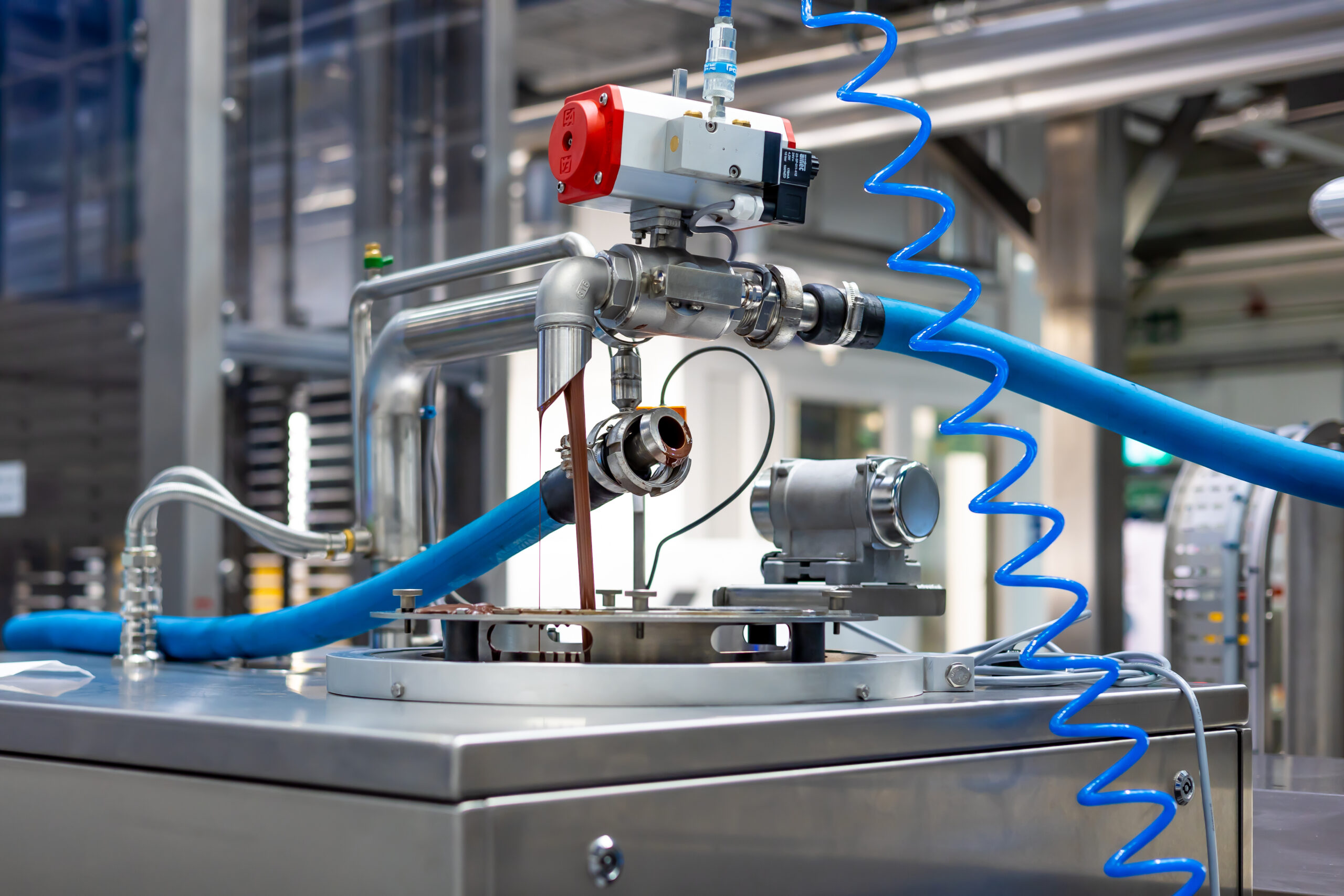

3D chocolate decorating machines are advanced tools that use precision KCM depositors for chocolate decoration.

Equipped with Computer-Aided Design (CAD) execution, these 3D depositors allow for precise decoration of various products, including hollow figures, chocolate lollies, bars and pralines.

Premier Forrester has 25 years of experience in sourcing decorating machines for chocolate manufacturers. Our principals’ 3D chocolate decorating machines are support by our after-sales care service, ensuring they fit smoothly into your processes.

Image Gallery

Key Product Features

- Precise decorating: The unique turning piston system provides maximum accuracy, even when the deposit volume is 0.01g.

- Precision extrusion technology: A special centring system allows the CAD depositor to decorate with two distinct colours, with no cooling needed between layers.

- Efficient production: RFID-technology allows assorted products to be made simultaneously in a production run as the machine recognises the mould and automatically runs the matching programme.

Product Specifications

Omega CAD

- Machine types: TCM 9, TCM 12/24

- Piston stoke: 32mm

- Z-axis: 100mm/150mm

- X-axis: 150mm/300mm

- Y-axis: 150mm/300mm

- Rifles: 35-42/2mm

- Pistons: 6-25mm

Alpha CAD

- Machine types: TCM 9, TCM 36/72

- Piston stoke: 52mm/60mm

- Z-axis: 150mm

- Y-axis: 150mm/300mm

- X-axis: 300mm

- Rifles: 30/2-90mm

- Pistons: 6-30mm

Eta/Theta CAD

- Machine types: TCM 9/18, TCM 36/72, TCM 72/144

- Piston stoke: 52mm/60mm/70mm

- Z-axis: 150mm

- Y-axis: 150/300mm

- X-axis: Eta – 300mm/400mm, Theta – 300mm/500mm

- Rifles: 30/2-90mm

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?