Polycarbonate Chocolate Moulds

Premier Forrester supplies industrial polycarbonate chocolate moulds for businesses across the UK and Europe.

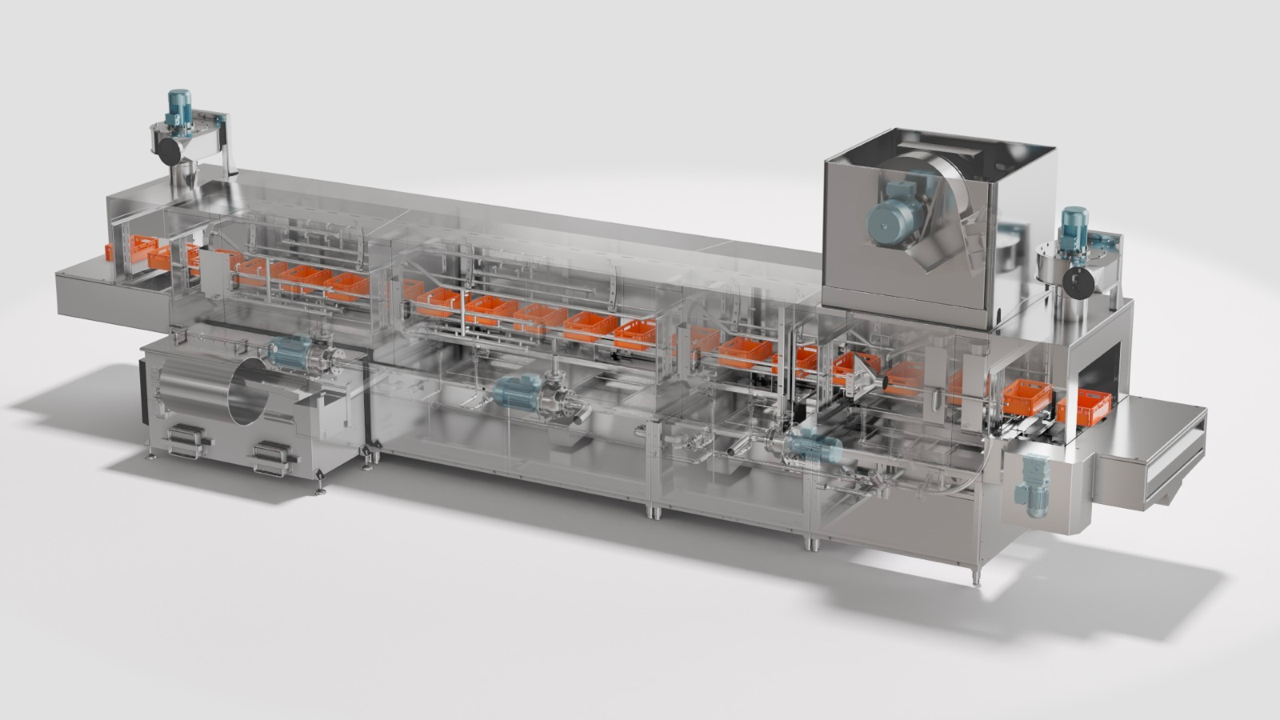

Standard and bespoke injection moulds can be used for everything from large, automated chocolate moulding lines to small, semi-automatic or manual operations.

Made from food-grade polycarbonate, this clear and durable plastic material is the preferred choice for professional chocolatiers due to its durability, flawless precision, and easy cleaning.

Our high-quality polycarbonate moulds will help you craft visually stunning chocolates with a smooth, glossy finish and intricate detailing.

Image Gallery

Key Features

- Durability and reusability: These clear moulds are designed to withstand the rigorous demands of an industrial production line. The robust polycarbonate material maintains the shape and integrity of the mould even with repeated use.

- Versatile design options: Polycarbonate chocolate moulds are available in a variety of shapes and designs. With sharp edges and intricate detailing, our moulds will help you craft professional chocolates that are visually stunning.

- Effortless cleaning: Designed for easy cleaning, the smooth, non-stick surface of polycarbonate moulds ensure that chocolate residue can be removed quickly and effortlessly.

Material Specifications

- Standard Polycarbonate: Our standard confectionery grade polycarbonate is reliable and rigid, complementing the rounded construction to create high-impact strength moulds. This food approved material can be finished with a hgih gloss or matt appearance to suit your product.

- Vofalon®: Impact-Modified Polycarbonate. Our unique mix provides higher impact resilience than standard polycarbonate to protect against the problems encountered by hammering and line issues. It also protects against the washing process to provide a greater return on investment.

- Vofasil: This unique Vormenfabriek recipe has been created to aid the de-moulding process. A copolymer of polycarbonate and siloxane, it protects your product quality and reduces wastage.

Applications

- Standard and bespoke injection moulds

- Double moulds

- One-shot moulds

- Carrier frames

- Demoulding plates

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?