Double and Tri Shot Depositors

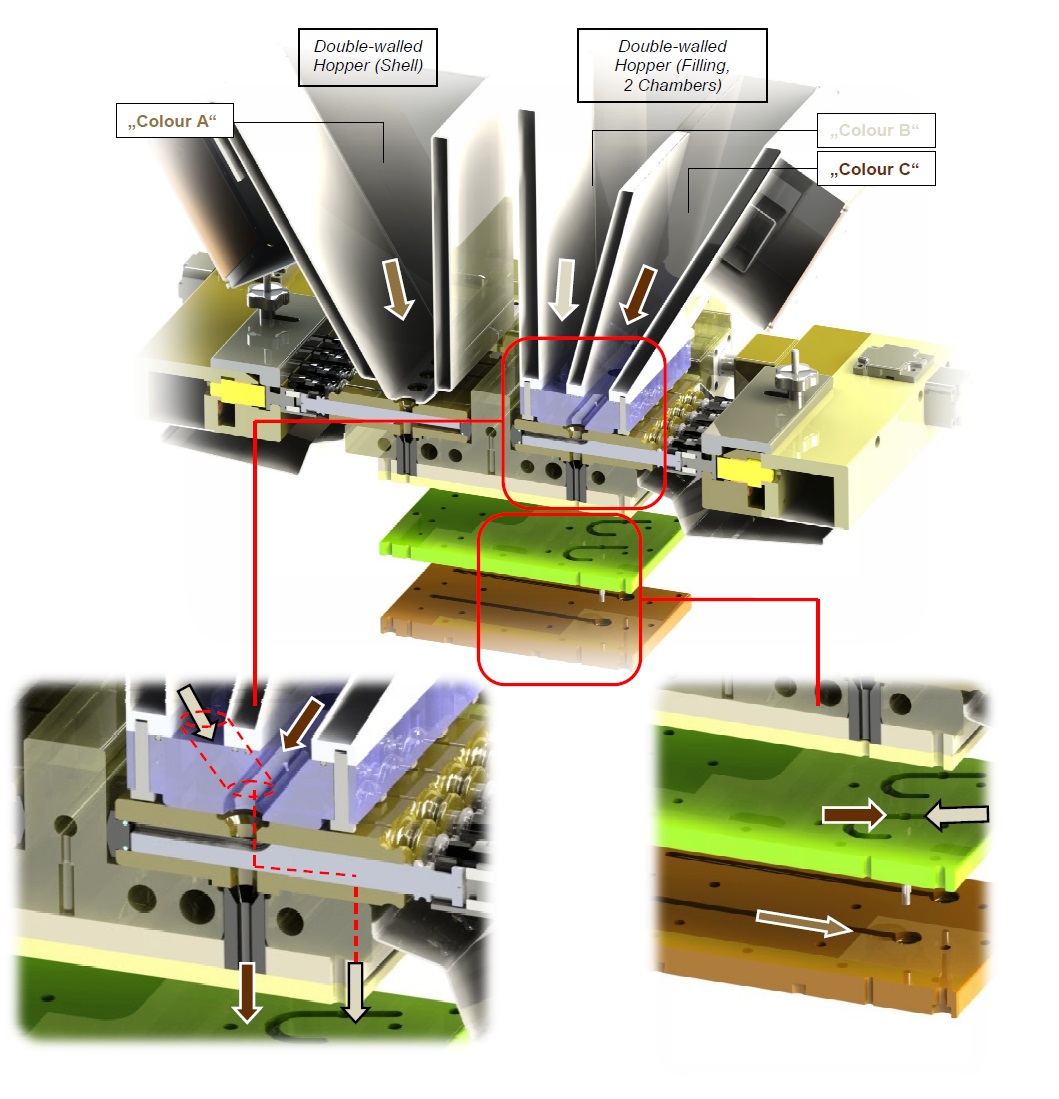

Double and tri shot chocolate depositors allow commercial chocolate makers to cast different shells or centres in a single operation, creating a mix of textures, flavours and designs.

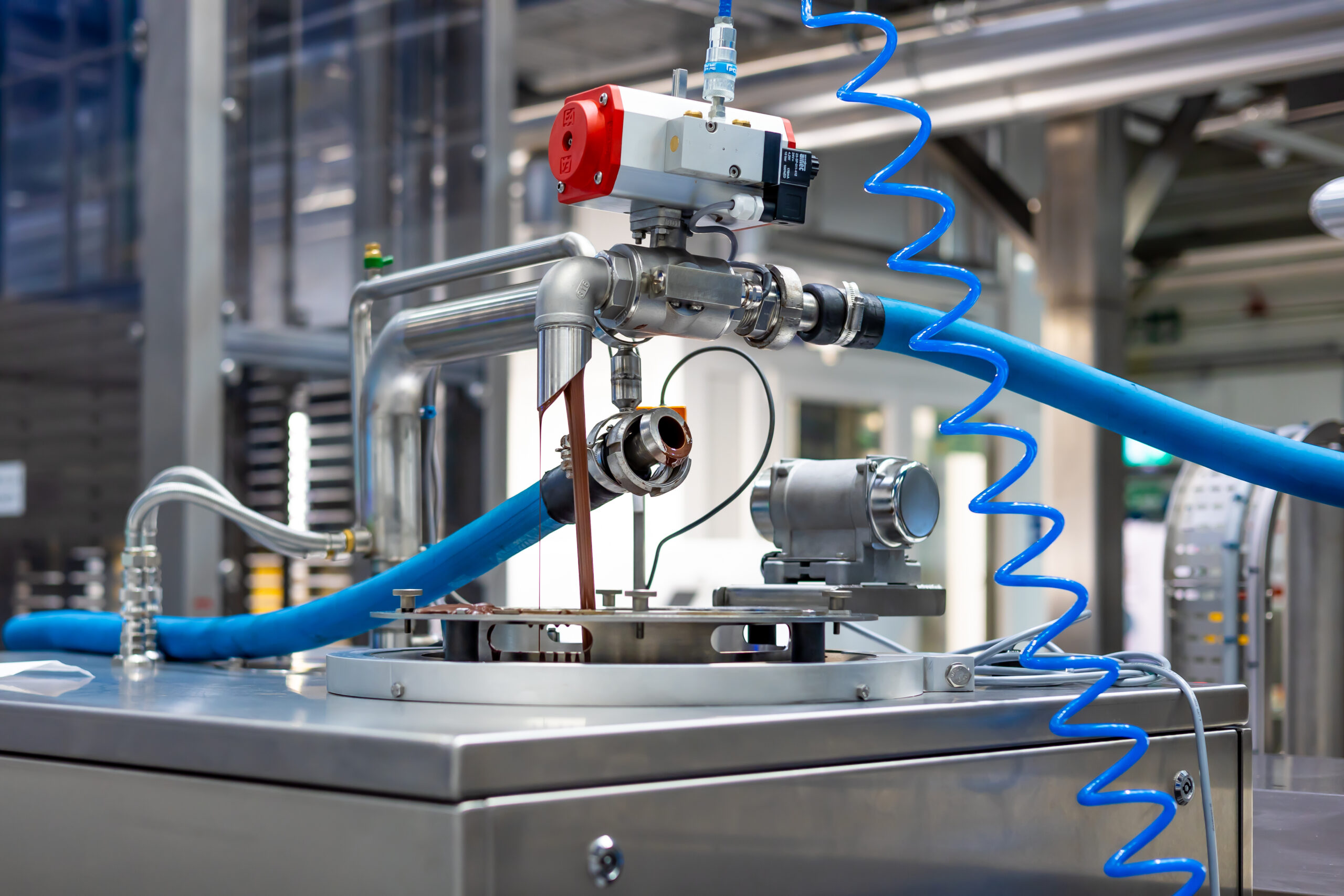

Efficient and innovative, these depositors streamline the chocolate production process, improving operational efficiency and offering more control over the final product.

Premier Forrester provides a complete after-sales support service for our customers, ensuring your chocolate machinery continues to run smoothly for years to come. Get in touch to learn more.

Image Gallery

Key Product Features

- Multi-shot depositing: This advanced depositor will introduce a new dimension to your confections with distinct layers of shells or centres.

- Precise dosing control: With meticulous dosing control, this depositor ensures accurate distribution of multiple layers of chocolate.

- Adaptable integration into existing lines: The double/tri shot chocolate depositor streamlines efficiency, allowing industrial chocolatiers to create complex, multi-layered confections with ease.

Product Specifications

Alpha

- Machine types: TCM 9, TCM 36/72, TCM 72/144

- Piston stoke: 52mm/60mm/70mm

- Z-axis: 150mm/300mm

- X-axis: 150mm/300mm

- Rifles: 35-90mm

- Pistons: 10-30mm

Alpha CAD

- Machine types: TCM 9, TCM 36/72

- Piston stoke: 52mm/60mm

- Z-axis: 150mm

- Y-axis: 150mm/300mm

- X-axis: 300mm

- Rifles: 30/2-90mm

- Pistons: 6-30mm

Eta/Theta

- Machine types: TCM 9/18, TCM 36/72, TCM 72/144

- Piston stoke: 52mm/60mm/70mm

- Z-axis: 150mm

- Y-axis: 150/300mm

- X-axis: Eta – 300mm/400mm, Theta – 300mm/500mm

- Rifles: 30/2-90mm

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?