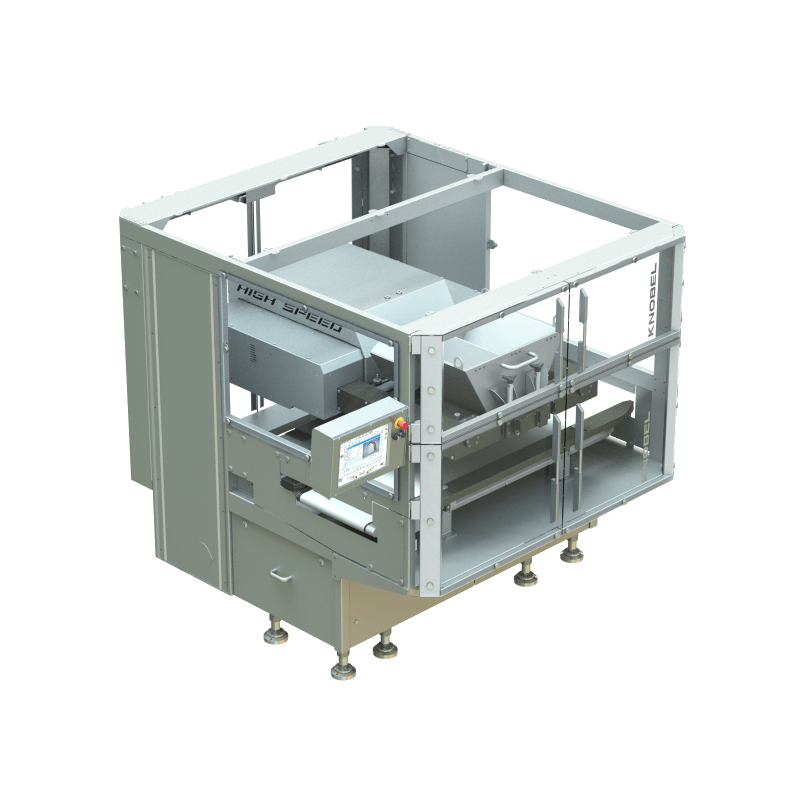

Chocolate Ball Mill Refiners

Chocolate ball mill refiners are specifically designed to fulfil all three chocolate production steps in one unit: mixing, refining and conching.

A revolving chamber houses rotating steel balls that meticulously grind and refine the cocoa nibs with other ingredients. Precise temperature controls help create a smooth texture and flavour, ensuring each batch of chocolate is consistently high-quality and uniform.

Premier Forrester has more than 25 years of experience in supplying chocolate machinery for artisans and industrial manufacturers. Your chocolate ball mill refiner will be supported by our wonderful after-sales team, who can help with everything from installation to operator training and servicing.

Image Gallery

Key Product Features

- Integrated Functionality: This ball refiner combines mixing, refining and conching processes into a single unit for efficient chocolate production.

- Customisable Refining Settings: Precise adjustments in grinding speed and intensity allow chocolate makers to achieve specific texture and flavour profiles.

- Advanced Temperature Controls: The machine maintains a precise temperature to ensure consistent chocolate quality.

Product Specifications

WAFA LAB

- Capacity (kg/h): 10

- Dimensions (mm): 850 x 750 x 1100

- Power requirement (kW): 2

- Water Consumption (l/h): 30

WAFA 100

- Capacity (kg/h): 100

- Dimensions (mm): 1170 x 1150 x 1800

- Power requirement (kW): 14

- Water Consumption (l/h): 40

WAFA 200

- Capacity (kg/h): 150-200

- Dimensions (mm): 1500 x 1200 x 2720

- Power requirement (kW): 27.5

- Water Consumption (l/h): 1500

WAFA 300

- Capacity (kg/h): 200-400

- Dimensions (mm): 1750 x 1575 x 2875

- Power requirement (kW): 37.5

- Water Consumption (l/h): 3000

Related Products

Find Out More

Premier Forrester support UK chocolate and confectionery manufacturers with a range of process solutions drawn from the world’s most innovative and experienced machinery manufacturers. We offer a comprehensive production support service, from advice on the best capital investments to meet your output requirements, to a variety of moulds, cooling equipment, and cleaning solutions. To discuss your project with one of our experienced engineers, please feel free to give us a call today.

Are you ready to start your next project?